Validating KPIs for the object-centric Inventory Management Control Center app

In the Inventory Management Control Center app’s Knowledge Model “Knowledge Model”, check that all the KPIs (key performance indicators) contain the correct business logic for your organization.

The main Knowledge Model for the Inventory Management Control Center app is “Knowledge Model”, which is at the top level in the app package. Work with this Knowledge Model to validate and change KPIs. “Knowledge Model” points to the base Knowledge Model stored in the Celonis Marketplace, which you can’t update directly. Changes that you make to the PQL formulas, KPI names, or formatting in “Knowledge Model” override the base Knowledge Model.

Each KPI in a Knowledge Model contains a PQL (Process Query Language) formula. Some KPIs are reused inside other KPIs as nested formulas. When you adjust the business logic in a single formula, and save it, the change is simultaneously reflected in all the KPIs that reuse the formula.

You work with Knowledge Models in Studio, and any changes you make are applied when you publish a new version of the app. You’ll need Analyst permissions on Studio and the Knowledge Model to modify any of the KPIs and their calculations. If you need training, check out the training track “Build Knowledge Models and Views” on the Celonis Academy.

Here’s how to work with the KPIs in “Knowledge Model”:

In the Celonis navigation menu, select Studio.

Find the Inventory Management Control Center app in your Studio space navigation.

Expand the package’s structure using the arrow.

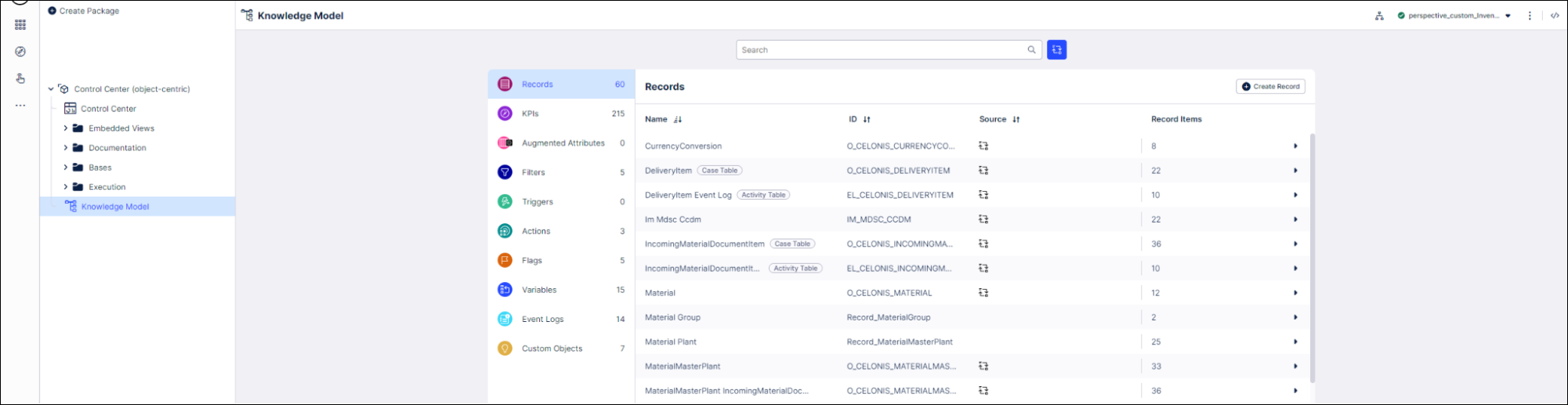

Select “Knowledge Model”.

Select the KPIs section of the Knowledge Model.

You can sort and search the KPIs using their name or ID. The prefix to the ID shows what type of component they are. At the end of these instructions, we’ve noted the most important KPIs to check.

To see and edit the full PQL formula and other settings for a KPI, click its row to open an editor. The editor automatically validates any changes that you make in the PQL formula.

If you want a fuller-featured PQL editor that lets you select from the tables and columns in your data, click on the pen icon next to the PQL formula.

If you need to disable a KPI or formula, click the three vertical dots at the top of the editor, and select Disable Scope, then click Disable to confirm. When you do this, the object can't be accessed or used anywhere in the package, including by other apps that depend on it.

If you make any changes to the business logic used in a KPI, update the end user documentation in the app’s Documentation folder.

When you’ve made changes to the KPIs, use the Publish Package button at the top of the screen in your Studio space to publish a new version of the app.

The in-app documentation that you can find using the “About this View” button in the Control Center view has information about the KPIs used in the tab and their calculations. Here’s the descriptions and the matching KPI IDs from the Knowledge Model:

KPI | Definition | KPI ID in Knowledge Model |

|---|---|---|

Excess Inventory Rate | The percentage of inventory on hand (i.e. total stock) which exceeds current target stock. Target stock is computed based on safety stock and cycle stock | KPI_MaterialMasterPlant_Calc_ExcessInventoryRate |

Material Availability | The average share of days on which a given material has had a stock greater than zero in a given timeframe. The time period considered for evaluation is given in parentheses, for example (1y) limits the input to the last twelve closed months | KPI_MaterialMasterPlant_Avg_MaterialAvailability |

Turnover Rate | The total consumption divided by the average inventory across the same time period based on valuated stock and consumption. Consumption is defined as the amount of consumed inventory in the considered timeframe | KPI_MaterialMasterPlant_Sum_TurnoverRate |

Service Level | The share of Sales Orders delivered between one day before and one day after the confirmed date during the considered timeframe | KPI_MaterialMasterPlant_Avg_ServiceLevelIsOnTime |

Days of Cover | The amount of days a particular material would have stock based on historical consumption levels, if no other replenishment took place | KPI_MaterialMasterPlant_Sum_DaysOfCover |

Supplier Reliability | The share of purchase orders received between five days before or one day after the scheduled date during the considered timeframe | KPI_MaterialMasterPlant_Avg_SupplierReliabilityIsOnTime |

Production Adherence | The share of Production Orders completed between one day before or one day after the scheduled date during the considered timeframe | KPI_MaterialMasterPlant_Avg_ProductionAdherenceIsOnTime |

Here’s a summary for the most important KPIs as they appear in the Knowledge Model:

KPI ID | Formula description |

|---|---|

CalculatedAttribute_MaterialMasterPlant_Stockout | Business logic for stockouts - identifies a stockout if inventory on hand and consignment stock are zero while safety stock is greater than zero |

CalculatedAttribute_MaterialMasterPlant_UnderStock | Business logic for under stock - identifies under stock if inventory on hand is between zero and safety stock, or if inventory on hand is zero while there is still consignment stock available |

CalculatedAttribute_MaterialMasterPlant_ExcessStock | Business logic for excess stock - identifies excess stock if excess inventory rate is greater than zero but smaller than 100% |

CalculatedAttribute_MaterialMasterPlant_ObsoleteStock | Business logic for obsolete stock - identifies obsolete stock if excess inventory rate equals 100% and there is no future demand |

CalculatedAttribute_MaterialMasterPlant_UntouchedStock | Business logic for untouched stock - identifies untouched stock as minimum unsold stock level if said minimum is greater than safety stock |

CalculatedAttribute_MaterialMasterPlant_InventoryClassification | Computes overall inventory classification |

CalculatedAttribute_PlannedOrder_IsOpen | Identifies open planned orders |

CalculatedAttribute_PurchaseRequisitionItem_IsOpen | Identifies open purchase requisitions |

CalculatedAttribute_PurchaseOrderItem_IsOpen | Identifies open purchase orders |

CalculatedAttribute_ProductionOrderItem_IsOpen | Identifies open production orders |

CalculatedAttribute_MaterialReservationItem_IsOpen | Identifies if a material reservation is open |

CalculatedAttribute_SalesOrderItem_IsOpen | Identifies open sales orders |

CalculatedAttribute_MaterialRequirement_IsOpen | Identifies if an independent material requirement is open |

CalculatedAttribute_PurchaseOrderItem_OnTimeDelivery | Indicates if a purchase order was received early, on time, or late - used to compute supplier reliability KPIs |

CalculatedAttribute_ProductionOrderItem_OnTimeDelivery | Indicates if a production order was completed early, on time, or late - used to compute production adherence KPIs |

CalculatedAttribute_SalesOrderItem_OnTimeDelivery | Indicates if a sales order was shipped early, on time, or late - used to compute service level KPIs (this logic is identical to the “On Time Deliveries” in the Celonis Order Management apps) |

While stockout and under stock scenarios rely on “hard values” like no inventory or a certain safety stock, the threshold for excess or obsolete stock is determined dynamically based on actual replenishment lead times and consumption. This threshold is referred to as “target stock”. Here’s the KPIs that influence it:

KPI ID | Formula description |

|---|---|

KPI_MaterialMasterPlant_Calc_ExcessInventoryRate | Share of excess in a material’s inventory |

KPI_MaterialMasterPlant_Calc_TargetStockQuantity | Threshold to excess stock - computed by adding current safety stock to initial stock (sometimes also referred to as cycle stock) |

Formula_MaterialMasterPlant_PuSum_ConsumptionQuantityConverted | Total of consumed quantity for a material in a given time period |

KPI_MaterialMasterPlant_Calc_ActualReplenishmentLeadTime | Actual replenishment lead time (Purchasing or Production) of a Material Plant combination - used if no past orders are available to compute an actual value |

KPI_MaterialMasterPlant_Calc_PlannedReplenishmentLeadTime | Planned replenishment lead time (Purchasing or Production) of a Material Plant combination - used if no past orders are available to compute an actual value |